Sustainability Guide

Ceramic Tile for a Safe and Healthy Environment

Creating a healthy environment is more important than ever before. Materials in areas where we spend significant time on a daily basis have the potential to affect our health both positively and negatively.

Creating a healthy environment is more important than ever before. Materials in areas where we spend significant time on a daily basis have the potential to affect our health both positively and negatively.

Ceramic-based materials are appreciated for their absence of harmful chemicals, easy maintenance, and the ability to promote cleanliness and hygiene. Every type of ceramic tile, including porcelain tile, quarry tile, wall tile, and pressed pavers, share all these benefits of ceramic tile:

- Eco-friendly maintenance: No harsh chemicals are necessary for cleaning! Wiping with some soap and water is all that’s needed to clean up most messes.

- Bacteria-resistant: Ceramic tile is inhospitable to the growth of bacteria and other microbes such as mold.

- Antimicrobial: Ceramic tile options are available that can suppress and even destroy harmful microorganisms, such as mold, fungi, bacteria, and viruses.

- Allergen-free: The high firing temperature of ceramic tile — generally more than 2000°F — burns off all organic compounds. Plus, ceramic’s nonporous surface doesn’t allow allergens in the environment such as dust, dirt, and pollen to penetrate.

- No volatile organic compounds (VOCs): VOCs are harmful gases that cause various health concerns and are emitted by virtually all nonceramic flooring types.

- No formaldehyde: Certain levels of formaldehyde can irritate asthma and other respiratory disorders, but ceramic tile does not contain formaldehyde.

- No polyvinyl chloride (PVC): PVC is a resin found in vinyl flooring that contains phthalates and organotins, both a concern among health experts.

- No plastic: The health and environmental concerns associated with plastic aren’t an issue for ceramic tile.

- Fire-resistant and nontoxic: Ceramic tile doesn’t melt, burn, or emit any toxic fumes when exposed to fire.

- Naturally occurring materials: Ceramic tile is a healthy choice for both you and the environment. The natural clays and other materials used to make ceramic tile are plentiful and are often sourced within 500 miles of manufacturing.

- Slip-resistant: Options are available that are classified for a wide range of appropriate uses in dry, wet, indoor, outdoor, and oil/grease conditions.

Healthy Outdoor Living Spaces

Ceramic tile is one of the most eco-friendly design choices for outdoor living spaces, allowing you to build alongside nature without causing nature any harm. This starts with the fact that ceramic tile introduces no harmful materials or toxins into the earth — no plastic-based materials, volatile organic compounds (VOCs), polyvinyl chloride (PVC), or formaldehyde.

Extra Resources

Energy & Life Cycle Cost Savings

- Exceptional Life-Cycle Cost = Best Value

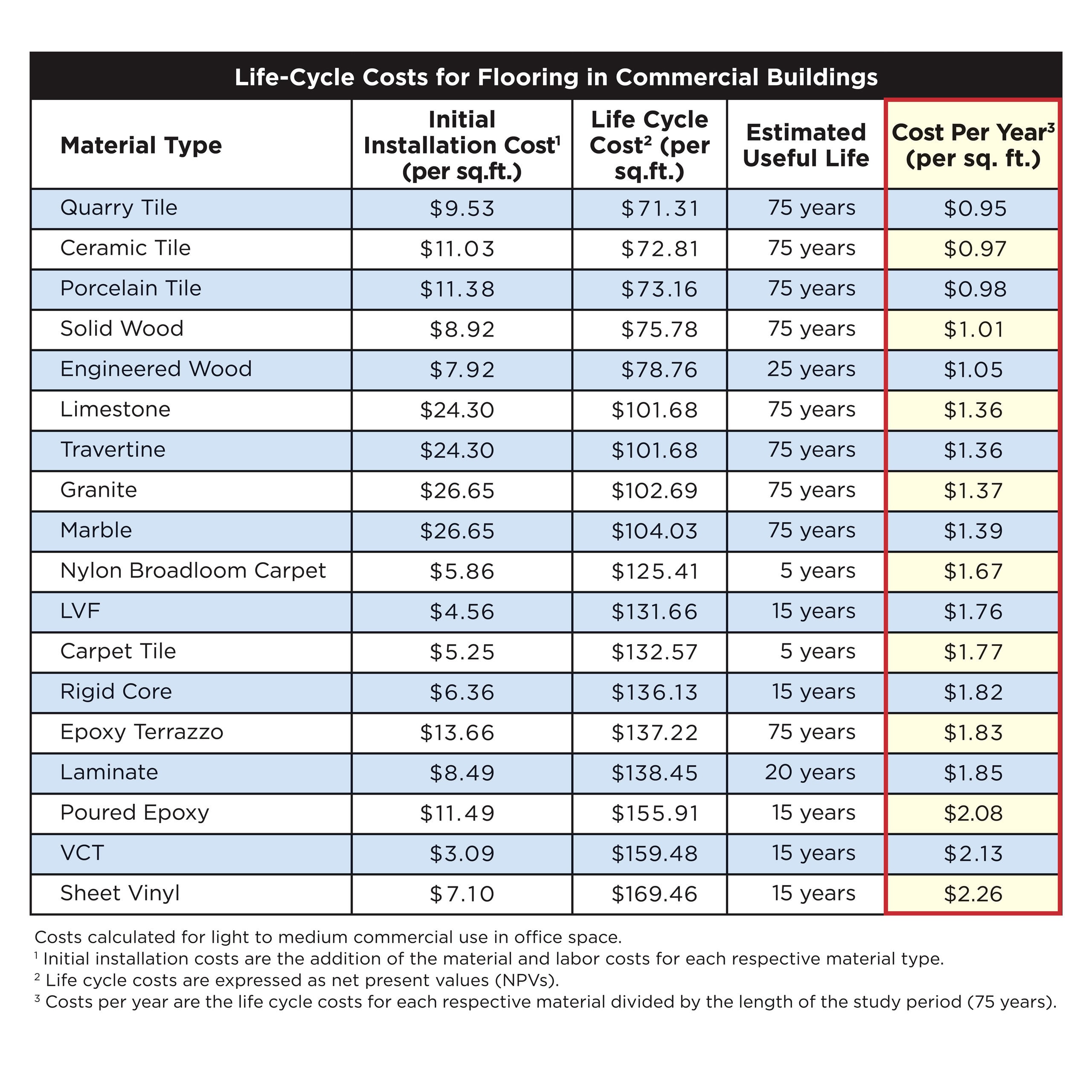

Ceramic tile has an exceptional life cycle. See the life-cycle cost study below for data on how ceramic tile outperforms other floor finishes in cost per square foot over time. Ceramic tile has been the preferred choice around the world for centuries for its timeless beauty and durability. - Regional Manufacturing and Raw Materials

With tile manufacturers in many regions of North America, tile and installation products made with local raw materials are widely available, greatly reducing the energy consumption and emissions of long-distance shipping. In many cases, the raw materials are mined within 500 miles of both the manufacturing facility and the job site. Plus, the clays and other materials used to make tile are plentiful. - Lower Energy Needs

Tile can reduce the amount of energy needed for heating and cooling because of its exceptional thermal mass. Additionally, ceramic tile is an ideal choice for ventilated façade projects. A ventilated tile façade can reduce a building’s energy consumption by 20% to 30% due to the natural chimney effect it creates between the structure and the cladding. Hot air is evacuated in summer, and insulation is more effective in winter. - Reduced Heat Island Effect

Using light-colored tiles instead of traditional paving materials can lower an area’s heat absorption, or heat island effect. Green buildings in urban areas in particular are required to reduce the potential heat island effect. - Recycled Content and Waste Reclamation

Many factories are effectively closed-loop facilities with zero waste, high levels of recycling, and efficient resource management. Also, ceramic tile finishes are among the few surfaces that can be salvaged in a major renovation and typically qualify for clean fill use.

Life Cycle Cost Analysis

Because a tile installation will last as long as the building it’s installed in, its environmental impacts are minimal when compared to other surface coverings that would have to be replaced numerous times over the life of the building. This also means that tile costs less per square foot over the long haul, whereas carpet, vinyl, and other floor coverings are significantly more expensive due to their replacement, maintenance, and refinishing requirements.

A study by Emily Lorenz, PE, F-ACI, an independent cost consultant, analyzed the life-cycle costs of various flooring options, including tile, hardwood, laminate, carpet, vinyl, and other popular choices. After appraising initial installation costs, replacement costs where relevant, and custodial maintenance expenses, for each option over its entire life cycle, the study found tile to be the most affordable flooring type. In fact, all types of tile cost less than $0.99 per square foot per year while poured epoxy, VCT, and sheet vinyl flooring were the most expensive over the life of a building. To see all the analyses, refer to the author’s full report.

Ceramic Tile’s Low Environmental Footprint

Environmental Product Declarations (EPDs) illustrate how ceramic tile delivers both performance and transparency in terms of sustainability, whether your project is residential or commercial.

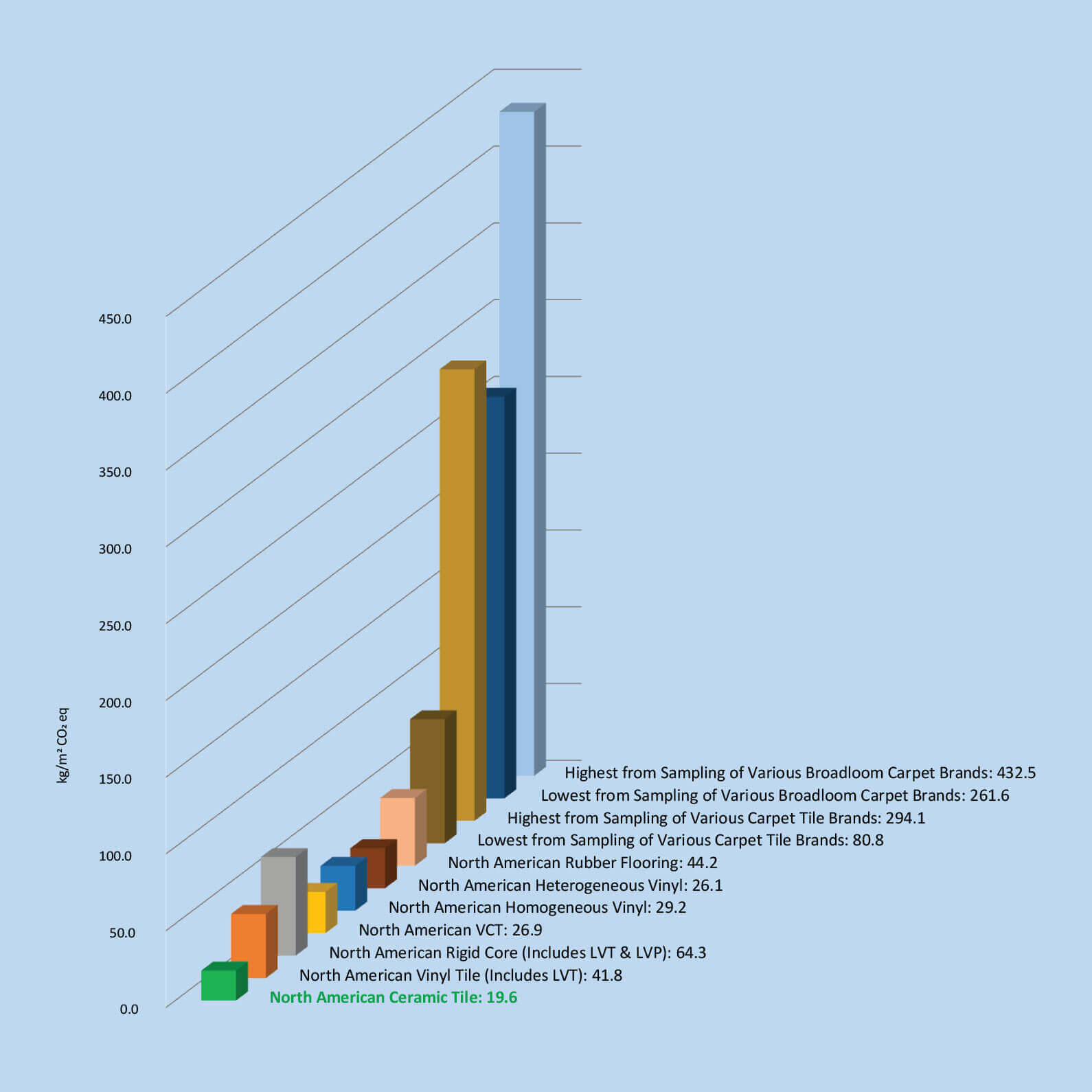

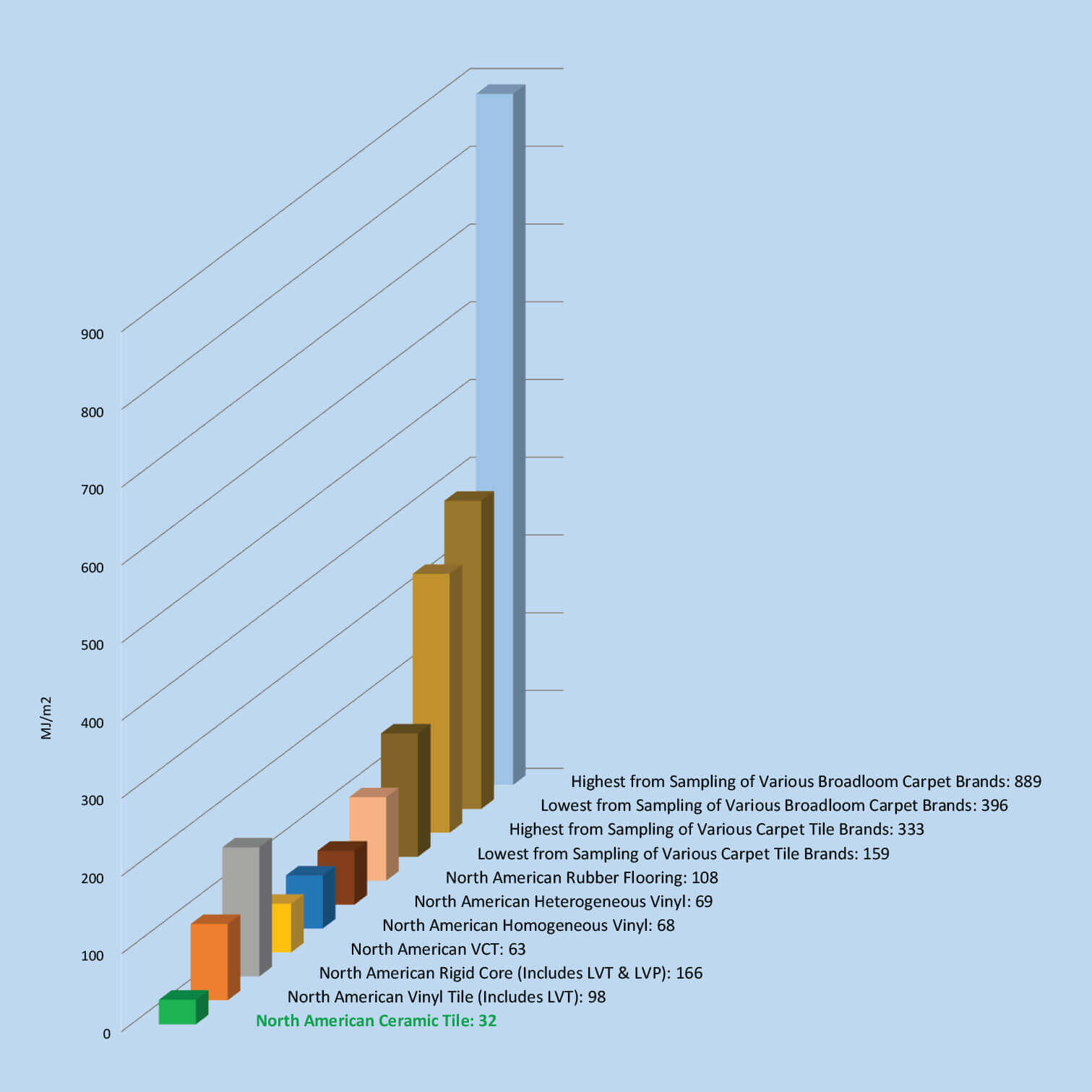

EPDs for North American-made ceramic tiles, mortars, and grouts all report very low 75-year environmental impacts per installed square meter. In fact, when the EPD for North American-made ceramic tile is compared to the generic EPDs for other types of flooring, developed under the same product category rules and using the same building service life, North American-made ceramic tile has the lowest overall environmental impact across all impact categories.

This includes the lowest (GWP) and the lowest Fossil Fuel Resource Depletion. GWP is the key factor used to determine a product’s embodied carbon. When compared to UL Certified EPDs for other types of flooring developed under the 2018 North American Flooring Product Category Rule, UL 10010-7, ceramic tile has the lowest 75-year GWP value, meaning it also has the lowest cradle to grave embodied carbon.

Over 85% of North American ceramic tiles are covered by the industry-wide ceramic tile EPD.

Simply stated, the industry-wide EPD is a report of the environmental footprint of the North American ceramic tile industry. The environmental impacts reported by the EPD are significantly lower than those reported by EPDs for flooring composed of plastic-based materials, such as luxury vinyl tiles and planks. In particular, a direct comparison to publicly available UL-Certified industry-wide EPDs for vinyl tile and rigid core board reveals the following:

- Vinyl tile’s 75-year GWP and fossil fuel resource depletion are two and three times higher, respectively, than ceramic tile’s GWP.

- Rigid core board’s 75-year GWP and fossil fuel resource depletion are three and five times higher, respectively, than ceramic tile’s fossil fuel resource depletion.

Regarding embodied carbon, it is important to consider a product’s cradle to grave GWP. A cradle-to-grave GWP assesses each stage of a product’s life cycle— production, construction, use, maintenance, refurbishment and replacement, and end of life.

Compared to other flooring products that need to be replaced more frequently, ceramic tile’s long life means it is both cost-effective and a smart choice for reducing embodied carbon, as well as other negative environmental impacts, including resource use, and demolition waste.

EPDs

Material Ingredient Guide

The Tile Council of North America (TCNA) and 17 North American tile manufacturers and TCNA members worked with WAP Sustainability, a leading consortium of sustainability experts with extensive familiarity with the ceramic tile industry, to produce GreenScreen Assessments® for the vast majority of material ingredients used by ceramic tile, mortar, and grout manufacturers. (GreenScreen® is a tool used worldwide to evaluate and benchmark chemicals and their associated hazards.)

The Tile Council of North America (TCNA) and 17 North American tile manufacturers and TCNA members worked with WAP Sustainability, a leading consortium of sustainability experts with extensive familiarity with the ceramic tile industry, to produce GreenScreen Assessments® for the vast majority of material ingredients used by ceramic tile, mortar, and grout manufacturers. (GreenScreen® is a tool used worldwide to evaluate and benchmark chemicals and their associated hazards.)

This industry effort produced the largest crowdfunded accumulation of GreenScreen Assessments® ever created in a first-ever Material Ingredient Guide.

The Material Ingredient Guide provides the following:

- Guidance for manufacturers when they are developing material ingredient reports

- A list of the ingredients most commonly used by North American manufacturers and references to in-depth chemical assessments of these ingredients

- Insights into satisfying green and healthy building criteria

The Material Ingredient Guide is representative of the ceramic tile industry’s commitment to consistency, thoroughness, and transparency in its product reporting, and comes on the back of many similar initiatives, such as environmental product declarations (EPDs) and Green Squared® product certifications. Following the steps outlined in the Material Ingredient Guide will make it easier to reference benchmarks when creating manufacturer inventories (MIs) and health product declarations (HPDs) to assist in obtaining green building optimization credits and comply with green building certification programs such as LEED, WELL, and the Living Building Challenge.

TCNA’s Material Ingredient Guide provides in-depth instructions and templates for manufacturers to follow when developing an HPD or MI. For both, a manufacturer must first have a product content inventory and screening/assessment results for each material ingredient included in the inventory. The Material Ingredient Guide’s GreenScreen Assessment BM scores for the ingredients common to ceramic tile, mortar, and/or grout can be helpful when developing and disclosing a product content inventory. Also, an HPD or MI developed using this information by a manufacturer who collaborated in the development of TCNA’s Material Ingredient Guide is offered third-party verification, based on an arrangement between TCNA and WAP Sustainability. A third-party verified HPD or MI with full GreenScreen Assessment BM scores is highly credible and facilitates green and healthy building “optimization” by providing a high level of material ingredient transparency.

For More Information

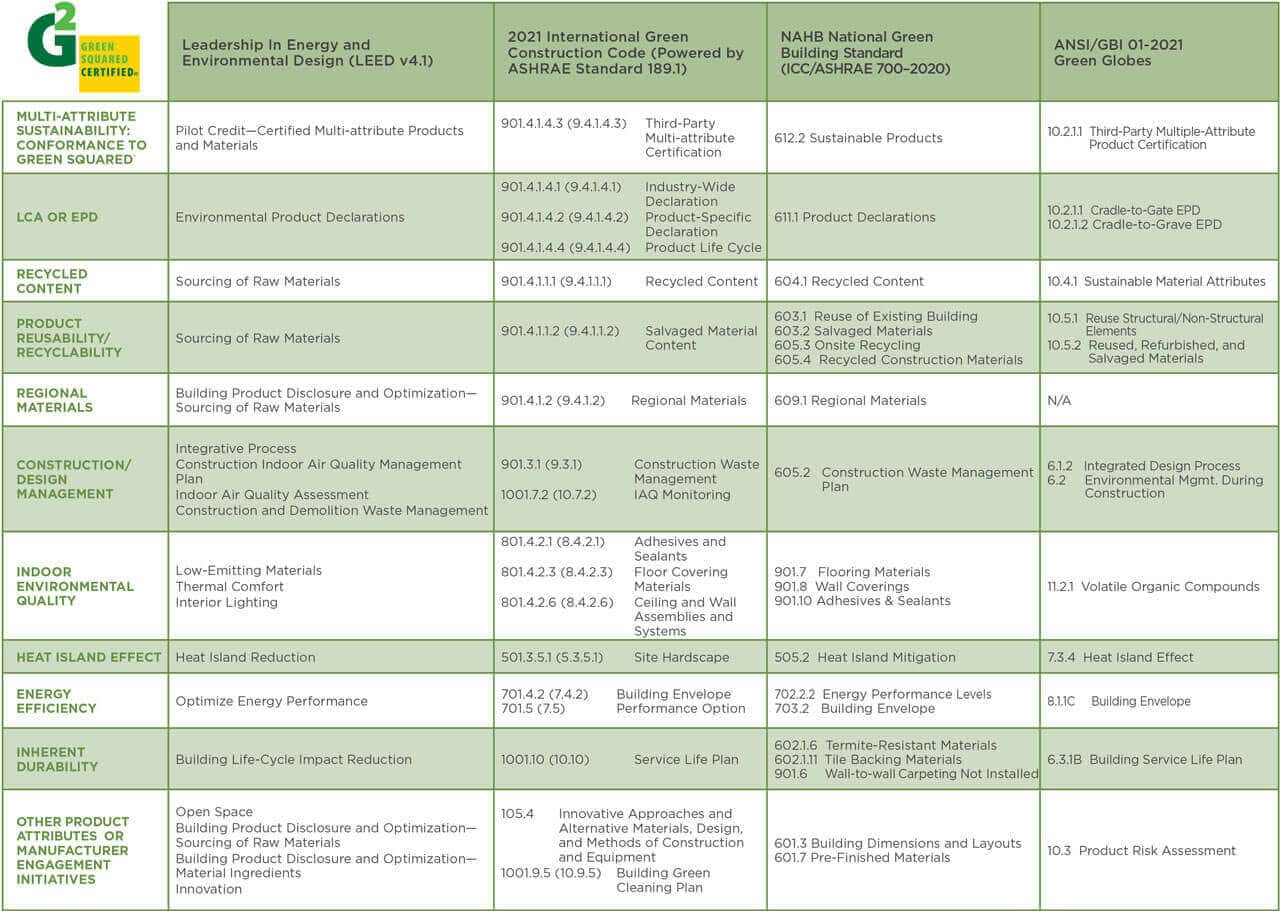

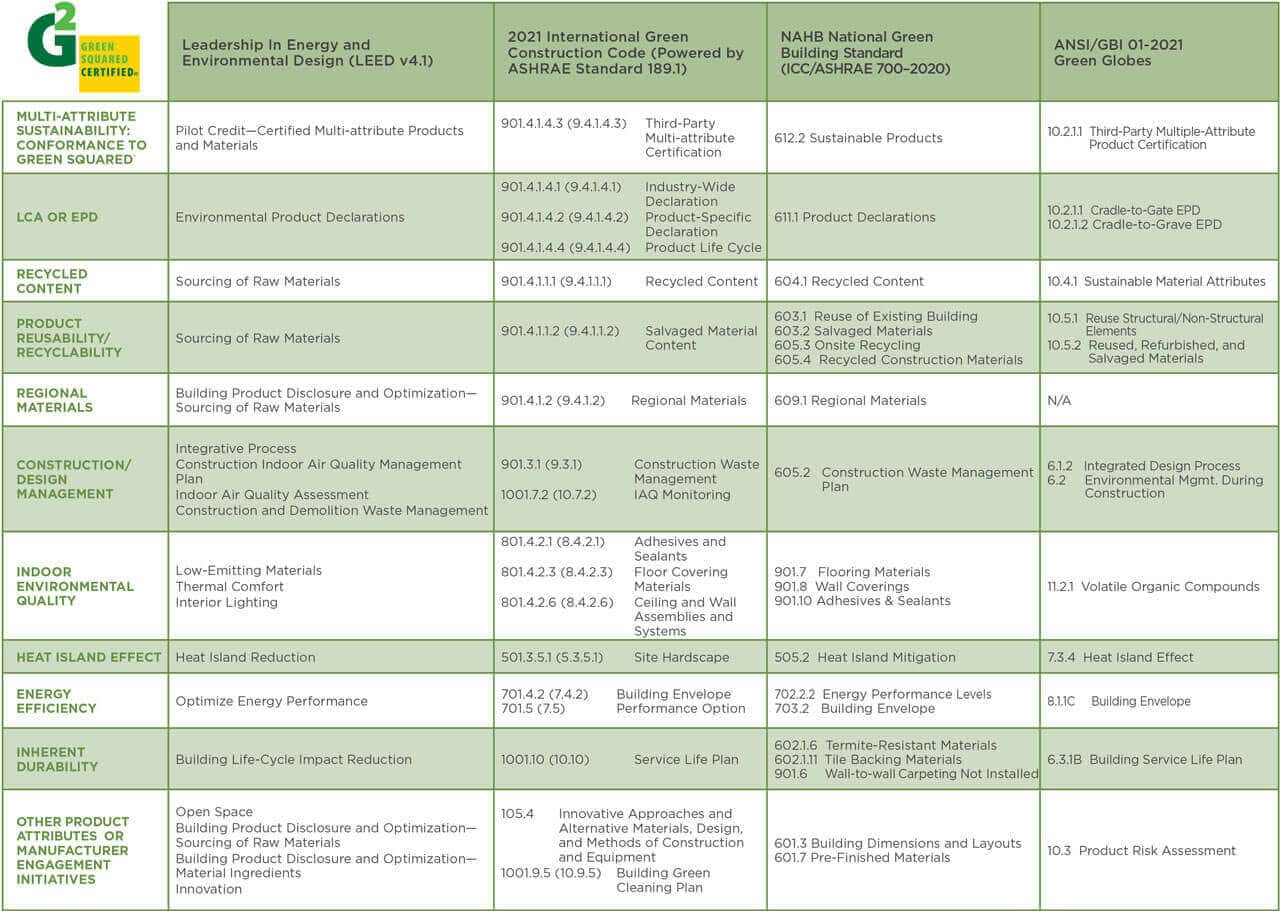

Green Squared Certified

Green Squared® is the world’s first multi-attribute sustainability standard and certification program for tile and the associated products needed to install tile, which includes ceramic and glass tiles, mortars, grouts, backer-boards, membranes, and other installation materials. Green Squared® is a cradle-to-grave performance standard that eliminates the need to cross-evaluate single-attribute sustainability claims.

Green Squared® is the world’s first multi-attribute sustainability standard and certification program for tile and the associated products needed to install tile, which includes ceramic and glass tiles, mortars, grouts, backer-boards, membranes, and other installation materials. Green Squared® is a cradle-to-grave performance standard that eliminates the need to cross-evaluate single-attribute sustainability claims.

For a product to be Green Squared Certified® means it meets the American National Standard Specifications for Sustainable Ceramic Tiles, Glass Tiles, and Tile Installation Materials (ANSI A138.1). To be in conformance, products must meet a broad array of rigorous sustainability requirements and electives, as set forth in the standard. The Green Squared® framework for product evaluation and certification is in accordance with ISO Type 1 environmental labeling and declaration requirements (ISO 14024). Products independently verified as conforming to the Green Squared® standard may bear the Green Squared Certified® mark.

Developed by an ANSI-accredited committee of green building professionals, manufacturers, distributors, installers, and other stakeholders, the Green Squared standard, ANSI A138.1, contains a spectrum of multi-attribute environmental and social criteria:

Environmental Product Characteristics

The first section of ANSI A138.1 standardizes product attributes such as the amount of recycled content, level of volatile organic emissions, amount of indigenous raw materials, etc.

Three levels of recycled content and reclaimed waste are defined in the standard. Level one is mandatory for conformance, and levels two and three are elective. Thresholds vary depending on product type.

There are also three standardized levels of indigenous raw material content. Recognizing the environmental burden from transportation, indigenous raw materials are those extracted within 500 miles of the manufacturing site. If transported by rail or sea, the limit is 2000 miles. All three levels are elective.

There are five standard attributes for sustainable packaging. All five are elective, but it is mandatory that at least one be achieved:

- Minimal packaging (packaging cannot exceed a specified percentage of the product weight)

- Recyclable packaging (a specified percentage of the packaging is recyclable)

- On-site reusable packaging (100% reusable on site)

- Biodegradable or compostable packaging (meets specific ASTM biodegradability criteria)

- Recycled content packaging (contains a specified percentage of recycled content)

Mandatory for conformance to ANSI A138.1, a product must meet industry standards for durability and performance. For example, tile must comply with ANSI A137.1. Also mandatory for conformance, a product shall have low (for installation products) or no (for tile) volatile organic compound (VOC) emissions. Environmentally friendly maintenance instructions must also be available.

Elective options for conformance to A138.1 include criteria for solar reflectance index (SRI), light reflectance value (LRV), and sound abatement. Also, electives for life cycle assessment (LCA) and/or environmental product declaration (EPD) are available.

Environmental Product Manufacturing & Raw Material Extraction

Sustainable production practices are mandatory for a product to conform to ANSI A138.1. Buildings containing process equipment shall not allow visible particulate matter (PM) emissions. Four standardized PM pollution control levels are based on grain size. The first is mandatory and the other three are elective.

The only types of fuels allowed are natural gas, LP gas, landfill-generated methane, and bio-based fuel. The usage of landfill-generated methane or bio-based fuel can earn elective credits. Elective credits can also be achieved through the use of low nitrogen oxide (NOx) burners and acid gas controls.

Also mandatory for a product to conform, the manufacturer of that product must have a written procurement policy for its raw material suppliers addressing social issues, environmental issues, and applicable requirements for mining laws. Additionally, the manufacturer is expected to maintain a list of all materials used to manufacture the product. As an elective, the manufacturer may choose to enter into a sustainability-based buying agreement with the raw material suppliers contributing at least 90% or more of the product by weight in aggregate.

For outsourced services, such as packaging or additional manufacturing services, manufacturers must require that their service providers have written sustainability policies.

Manufacturers are required to have an environmental management plan that addresses waste minimization, lighting efficiency, heating fuel usage, electricity consumption, and water

conservation. There are elective options for minimal water discharge, renewable energy usage, cogeneration, heat recovery or combined heat and power integration, ASHRAE auditing, and ISO 14001 environmental plan registration.

As electives, several innovative criteria for waste diversion are established. These include incorporation of waste into other manufacturers’ products or beneficial reuse projects, donation of finished products to charitable organizations in lieu of disposal, and recycling/reuse of incoming shipping materials.

End of Product Life Management

This section of the standard opens with the following preface:

Inherently, tile products are durable, inert, and intended to have life spans as long as the buildings in which they are installed. They are engineered to serve as permanent finishes capable of outlasting multiple generations of building occupants. Tile product end of life management is pertinent to building demolition waste and small quantities of waste generated during construction.

It is perhaps self-evident — but worth noting — that a product with a long lifetime is more sustainable than a similar product with a short lifespan. When considering the environmental, social, and economic sustainability of a product, all relevant impacts are repeated each time that product is replaced. Ideally, a product’s expected service life is at least as long as the building in which it is installed, in which case its impacts are considered only once.

Although a tiled finish is inherently durable and typically desirable for a lifetime, there are instances in which end of product life must be addressed. Thus, there are end of product life management electives in ANSI A138.1 that are intended for instances where buildings are demolished, scrap waste is generated during construction, or a remodel occurs.

The first end of product life management elective option requires that the product be eligible for use as clean fill. To satisfy this elective, a manufacturer shall provide documentation verifying that the product is inert and solid such that it can potentially be considered along with other eligible construction and demolition debris for state and local Clean Fill acquisition initiatives.

A second elective requires an end of product life collection plan. To satisfy this elective, the manufacturer shall establish and implement a plan that addresses the collection, processing, and recycling or re-tasking of a product for other purposes once the product’s useful life is completed.

Progressive Corporate Governance

Mandatory for conformance to the standard, a manufacturer shall have a written and implemented social responsibility strategy that addresses at least the following: labor law compliance, forced labor prohibitions, child labor prohibitions, environmental regulation compliance, health and safety regulation compliance, and community involvement.

As an elective, the manufacturer may choose to participate in a voluntary safety program such as OSHA Safety Consultation, Voluntary Protection Program (VPP), or OHSAS 18001.

It is mandatory that all green marketing claims made by the manufacturer be in compliance with the Federal Trade Commission (FTC) Fair Packaging and Labeling Act (FPLA) Green Guides (publicly available) that indicate how the FTC applies Section 5 of the FPLA, prohibiting unfair or deceptive acts or practices in environmental claims.

As an elective, the manufacturer may choose to regularly engage in its community, building upon the community involvement plan established in its mandatory social responsibility strategy.

Also, as an elective, the manufacturer may publicly disclose on an annual basis one of the following: utilities consumption, registered Environmental Management System (EMS) data, or Life Cycle Assessment (LCA) data.

An elective credit is also available if a manufacturer provides a detailed sustainability report each year, conforms to the requirements of the Global Reporting Initiative (GRI), or is

selected for inclusion in the Dow Jones Sustainability Index (DJSI).

If a manufacturer has at least one facility with LEED® or Green Globes certification, an elective credit is also available.

Additionally, manufacturers are required to have a program in place that demonstrates continued conformance to the specified criteria of ANSI A138.1/Green Squared for all pertinent products.

Innovation

Technological advancement and outstanding achievement, well beyond what is required, can be key to the development of sustainable products and operations. ANSI A138.1 allows products to achieve conformance, in part, through innovation. This may involve exceptional performance well above the requirements set forth in other sections of the standard, and/or innovative performance recognized by the ANSI ASC A108 Committee in categories not otherwise addressed by the standard.

A product may earn up to two electives through exceptional conformance if quantitative criteria already addressed by the standard are greatly exceeded. Either the most stringent threshold already established for a specific criterion must be exceeded by one and a half times, or certain requirements defined in the standard’s Appendix C must be met.

For sustainability attributes not directly addressed by the standard, an evolving list of approved innovations is managed by the ANSI ASC A108 Committee. Innovations not included in this list can be added if they are submitted to and approved by the Committee. This can include ecological attributes or processes not otherwise addressed by the standard or innovative corporate governance.

A product may also earn a fourth innovation elective if the product’s carbon footprint is provided and prescriptive measures were taken to reduce either the product’s or the manufacturing organization’s greenhouse gases.

- Product Characteristics

-

Environmental Product Characteristics

The first section of ANSI A138.1 standardizes product attributes such as the amount of recycled content, level of volatile organic emissions, amount of indigenous raw materials, etc.

Three levels of recycled content and reclaimed waste are defined in the standard. Level one is mandatory for conformance, and levels two and three are elective. Thresholds vary depending on product type.

There are also three standardized levels of indigenous raw material content. Recognizing the environmental burden from transportation, indigenous raw materials are those extracted within 500 miles of the manufacturing site. If transported by rail or sea, the limit is 2000 miles. All three levels are elective.

There are five standard attributes for sustainable packaging. All five are elective, but it is mandatory that at least one be achieved:

- Minimal packaging (packaging cannot exceed a specified percentage of the product weight)

- Recyclable packaging (a specified percentage of the packaging is recyclable)

- On-site reusable packaging (100% reusable on site)

- Biodegradable or compostable packaging (meets specific ASTM biodegradability criteria)

- Recycled content packaging (contains a specified percentage of recycled content)

Mandatory for conformance to ANSI A138.1, a product must meet industry standards for durability and performance. For example, tile must comply with ANSI A137.1. Also mandatory for conformance, a product shall have low (for installation products) or no (for tile) volatile organic compound (VOC) emissions. Environmentally friendly maintenance instructions must also be available.

Elective options for conformance to A138.1 include criteria for solar reflectance index (SRI), light reflectance value (LRV), and sound abatement. Also, electives for life cycle assessment (LCA) and/or environmental product declaration (EPD) are available.

- Raw Materials & Manufacturing

-

Environmental Product Manufacturing & Raw Material Extraction

Sustainable production practices are mandatory for a product to conform to ANSI A138.1. Buildings containing process equipment shall not allow visible particulate matter (PM) emissions. Four standardized PM pollution control levels are based on grain size. The first is mandatory and the other three are elective.

The only types of fuels allowed are natural gas, LP gas, landfill-generated methane, and bio-based fuel. The usage of landfill-generated methane or bio-based fuel can earn elective credits. Elective credits can also be achieved through the use of low nitrogen oxide (NOx) burners and acid gas controls.

Also mandatory for a product to conform, the manufacturer of that product must have a written procurement policy for its raw material suppliers addressing social issues, environmental issues, and applicable requirements for mining laws. Additionally, the manufacturer is expected to maintain a list of all materials used to manufacture the product. As an elective, the manufacturer may choose to enter into a sustainability-based buying agreement with the raw material suppliers contributing at least 90% or more of the product by weight in aggregate.

For outsourced services, such as packaging or additional manufacturing services, manufacturers must require that their service providers have written sustainability policies.

Manufacturers are required to have an environmental management plan that addresses waste minimization, lighting efficiency, heating fuel usage, electricity consumption, and water

conservation. There are elective options for minimal water discharge, renewable energy usage, cogeneration, heat recovery or combined heat and power integration, ASHRAE auditing, and ISO 14001 environmental plan registration.As electives, several innovative criteria for waste diversion are established. These include incorporation of waste into other manufacturers’ products or beneficial reuse projects, donation of finished products to charitable organizations in lieu of disposal, and recycling/reuse of incoming shipping materials.

- End of Product Life Management

-

End of Product Life Management

This section of the standard opens with the following preface:

Inherently, tile products are durable, inert, and intended to have life spans as long as the buildings in which they are installed. They are engineered to serve as permanent finishes capable of outlasting multiple generations of building occupants. Tile product end of life management is pertinent to building demolition waste and small quantities of waste generated during construction.

It is perhaps self-evident — but worth noting — that a product with a long lifetime is more sustainable than a similar product with a short lifespan. When considering the environmental, social, and economic sustainability of a product, all relevant impacts are repeated each time that product is replaced. Ideally, a product’s expected service life is at least as long as the building in which it is installed, in which case its impacts are considered only once.

Although a tiled finish is inherently durable and typically desirable for a lifetime, there are instances in which end of product life must be addressed. Thus, there are end of product life management electives in ANSI A138.1 that are intended for instances where buildings are demolished, scrap waste is generated during construction, or a remodel occurs.

The first end of product life management elective option requires that the product be eligible for use as clean fill. To satisfy this elective, a manufacturer shall provide documentation verifying that the product is inert and solid such that it can potentially be considered along with other eligible construction and demolition debris for state and local Clean Fill acquisition initiatives.

A second elective requires an end of product life collection plan. To satisfy this elective, the manufacturer shall establish and implement a plan that addresses the collection, processing, and recycling or re-tasking of a product for other purposes once the product’s useful life is completed.

- Corporate Governance

-

Progressive Corporate Governance

Mandatory for conformance to the standard, a manufacturer shall have a written and implemented social responsibility strategy that addresses at least the following: labor law compliance, forced labor prohibitions, child labor prohibitions, environmental regulation compliance, health and safety regulation compliance, and community involvement.

As an elective, the manufacturer may choose to participate in a voluntary safety program such as OSHA Safety Consultation, Voluntary Protection Program (VPP), or OHSAS 18001.

It is mandatory that all green marketing claims made by the manufacturer be in compliance with the Federal Trade Commission (FTC) Fair Packaging and Labeling Act (FPLA) Green Guides (publicly available) that indicate how the FTC applies Section 5 of the FPLA, prohibiting unfair or deceptive acts or practices in environmental claims.

As an elective, the manufacturer may choose to regularly engage in its community, building upon the community involvement plan established in its mandatory social responsibility strategy.

Also, as an elective, the manufacturer may publicly disclose on an annual basis one of the following: utilities consumption, registered Environmental Management System (EMS) data, or Life Cycle Assessment (LCA) data.

An elective credit is also available if a manufacturer provides a detailed sustainability report each year, conforms to the requirements of the Global Reporting Initiative (GRI), or is

selected for inclusion in the Dow Jones Sustainability Index (DJSI).If a manufacturer has at least one facility with LEED® or Green Globes certification, an elective credit is also available.

Additionally, manufacturers are required to have a program in place that demonstrates continued conformance to the specified criteria of ANSI A138.1/Green Squared for all pertinent products.

- Innovation

-

Innovation

Technological advancement and outstanding achievement, well beyond what is required, can be key to the development of sustainable products and operations. ANSI A138.1 allows products to achieve conformance, in part, through innovation. This may involve exceptional performance well above the requirements set forth in other sections of the standard, and/or innovative performance recognized by the ANSI ASC A108 Committee in categories not otherwise addressed by the standard.

A product may earn up to two electives through exceptional conformance if quantitative criteria already addressed by the standard are greatly exceeded. Either the most stringent threshold already established for a specific criterion must be exceeded by one and a half times, or certain requirements defined in the standard’s Appendix C must be met.

For sustainability attributes not directly addressed by the standard, an evolving list of approved innovations is managed by the ANSI ASC A108 Committee. Innovations not included in this list can be added if they are submitted to and approved by the Committee. This can include ecological attributes or processes not otherwise addressed by the standard or innovative corporate governance.

A product may also earn a fourth innovation elective if the product’s carbon footprint is provided and prescriptive measures were taken to reduce either the product’s or the manufacturing organization’s greenhouse gases.

Specifying Green Squared

LEED v4.1

Under the LEED pilot credit, Certified Multi-Attribute Products and Materials, a point toward LEED certification can be earned by using products from manufacturers who have confirmed multiple environmental attributes through an independent, third-party certification, such as Green Squared®.

In order to achieve this point, at least 25%, by cost, of the total value of permanently installed products in a project must have earned certification under any of the following programs:

- Level® certification for furniture

- NSF 140 certification for carpet

- NSF 332 certification for resilient flooring

- Green Squared certification for tiles and tile installation materials

- UL 100 certification for wall board

- NSC 373 certification for natural stone

- NSF 343 for wallcoverings

- NSF 347 for roofing membranes

Additionally, the product literature must disclose which sections of the relevant multi-attribute sustainability standard were met. An LCA (life-cycle assessment) conforming to ISO 14044 must be available as well, either as a component of or in addition to the product’s multi-attribute certification.

Tiles or installation materials that are Green Squared Certified® and for which an LCA is available (or which meet section 3.8.1 of Green Squared®/ANSI A138.1) can contribute:

Tiles or installation materials that are Green Squared Certified® and for which an LCA is available (or which meet section 3.8.1 of Green Squared®/ANSI A138.1) can contribute:

- 50% of the total product cost for baseline certification

- 75% of the total product cost if ANSI 138.1 Level 2 criteria for recycled/reclaimed content and/or Level 2 criteria for indigenous raw materials were met as part of the certification

- 100% of the total product cost if ANSI A138.1 Level 3 criteria for recycled/reclaimed content and/or Level 3 criteria for indigenous raw materials were met as part of the certification

Sample calculation for a project with $1,000,000 in permanently installed products, including $80,000 of Green Squared Certified tile and $20,000 of Green Squared Certified mortar that meets ANSI A138.1 Level 3 criteria for indigenous raw materials:

Tile installation contribution to the 25%, by cost, of the total value of permanently installed products in the project:

(0.5) ($80k tile value) + (1.0) ($20k mortar value) = 6%

$1M (all materials value)

In the example above, the contribution of Green Squared Certified® tiles and installation materials toward the 25% minimum would be 6%.

ANSI/GBI 01-2021 Green Globes

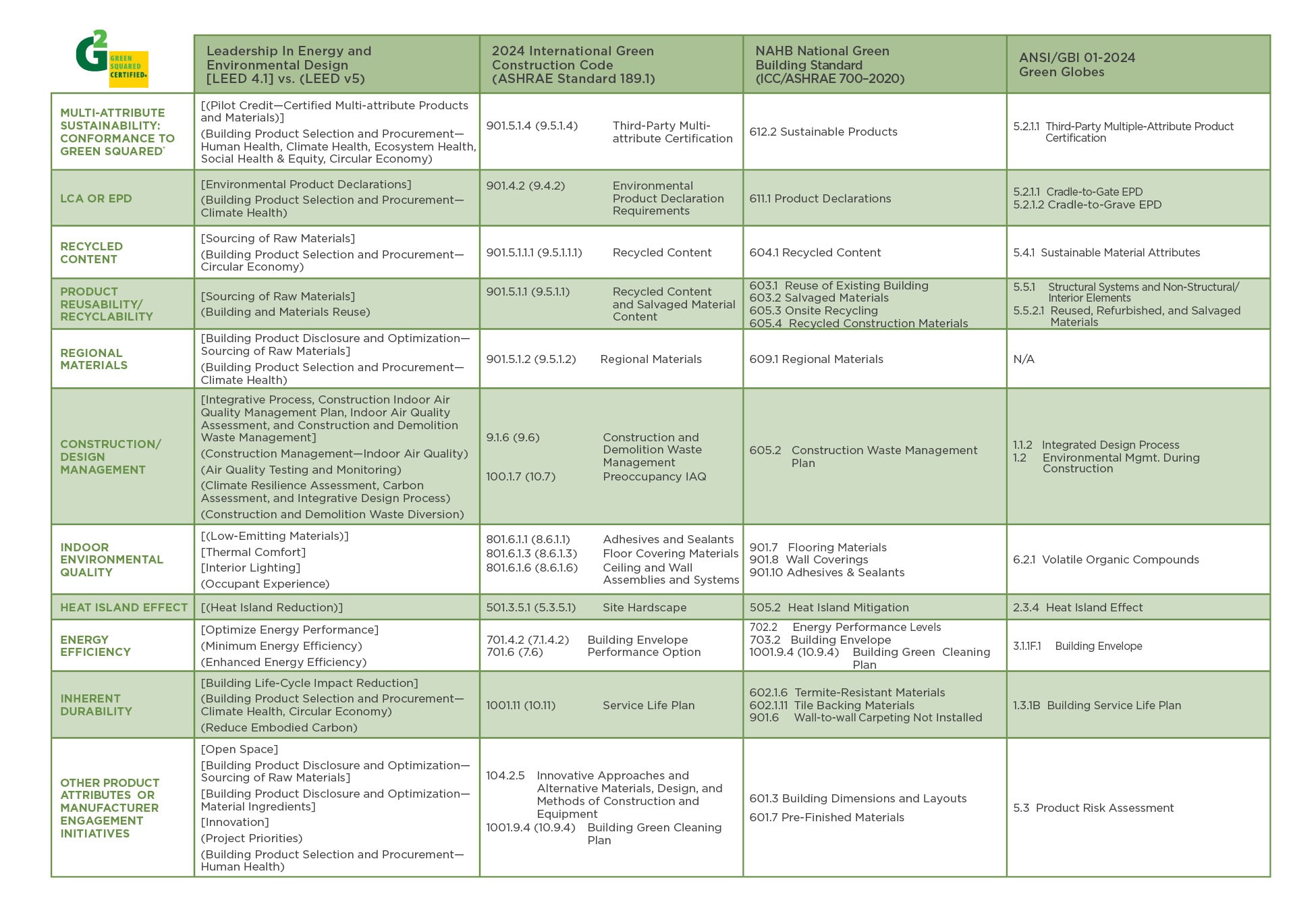

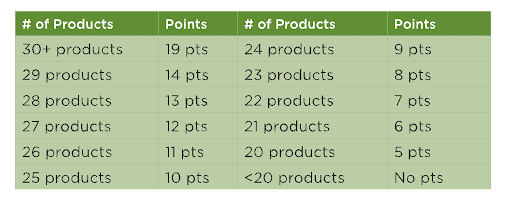

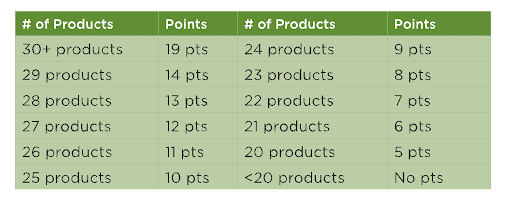

Under the provisions of Section 10.2, ANSI/GBI 01-2021 Product Life Cycle, using Green Squared Certified® products can contribute toward the 19 available points for using products with EPDs or that are third-party certified to multi-attribute standards. Points are awarded for using products with:

![]()

Points are awarded based on the number of products used, as follows:

Without limit, using Green Squared Certified® tiles or installation materials will contribute to this requirement. Products that also have an LCA or EPD can contribute double.

Without limit, using Green Squared Certified® tiles or installation materials will contribute to this requirement. Products that also have an LCA or EPD can contribute double.

Sample calculation for a project with six Green Squared Certified® tiles, six Green Squared Certified® grouts, one Green Squared Certified® mortar, and nine other products certified under their respective industry programs:

= 22 total products (7 points)

Using the above example, tile’s contribution is 13 out of 22 products, or 59%.

Sample calculation for the same project, but with tile that is Green Squared Certified® and has an LCA or EPD:

[(13 Green Squared Certified products with LCA or EPD) x 2]

+

9 other compliant products

= 35 total products (19 points)

Using the above example, although 35 total products are achieved, only 30 are required to obtain the maximum points tier. Toward the threshold, tile’s contribution is 26 out of 30 products, or 87%.

International Green Construction Code (IgCC) Powered by ASHRAE Standard 189.1

About IgCC: An initiative of the International Code Council (ICC), IgCC was developed as model code language for states and municipalities to establish baseline sustainability requirements for new and existing commercial buildings.

About ASHRAE 189.1: An ANSI-accredited standard, ASHRAE 189.1 was written to be incorporated into governing jurisdictions’ codes and ordinances for commercial buildings and enforced by building officials and inspectors.

IgCC and ASHRAE Standard 189.1 are now integrated into a single model code and standard for high-performance buildings.

For compliance with the IgCC, specifically Section 901.4.1.4.3 (ASHRAE 189.1 Section 9.4.1.4.3), Multiple-Attribute Product Declaration or Certification, at least 10 different products installed in the building at the time of occupancy shall have a generic EPD, have a proprietary EPD, conform to a third-party multi-attribute certification, or have a third-party reviewed life cycle assessment (LCA).

Each Green Squared Certified® tile or installation material used on a project counts as two products toward the 10-product threshold, as the Green Squared® standard is one of the multi-attribute certification programs specified by the standard.

Each Green Squared Certified® tile or installation material used on a project counts as two products toward the 10-product threshold, as the Green Squared® standard is one of the multi-attribute certification programs specified by the standard.

NAHB National Green Building Standard

Commonly referred to as ICC 700, NAHB’s National Green Building Standard is an ANSI-accredited specification for residential construction. Green Squared Certified® tiles and installation materials can help achieve points under section 612.2, Sustainable Products.

Three points are awarded if 50% or more, based on square footage, of all tiles installed in a project have been Green Squared Certified. In order for such tiles to qualify, tiles must make up at least 30% of the floor or wall area of the project.

Three points are awarded if 50% or more, based on square footage, of all the tile installed in a project has been Green Squared Certified®. In order for such tiles to qualify, tile in general must make up at least 30% of the floor or wall area of the project.

Three points are awarded if 50% or more, based on square footage, of all the tile installed in a project has been Green Squared Certified®. In order for such tiles to qualify, tile in general must make up at least 30% of the floor or wall area of the project.

GSA P-100 Facilities Standards

This standard incorporates sustainability criteria into design standards for the construction of government-funded buildings. Section 3.4 (Interior Performance) sets forth several provisions for ceramic tile:

- The “Baseline” and Tier 1 High Performance provisions specify that tiles conform to ANSI A137.1, the ANSI standard for ceramic tile, and be Green Squared Certified®.

- The Tier 2 High Performance and Tier 3 High Performance provisions specify that tiles conform to ANSI A137.1, the ANSI standard for ceramic tile, be Green Squared Certified®, and have a publicly-available EPD.

Green Squared Certified® tiles and installation materials satisfy GSA’s baseline and Tier 1 High Performance tiling requirements. Green Squared Certified® products that also have an EPD are eligible for use on Tier 2 and Tier 3 federal building projects.

Green Squared Certified® tiles and installation materials satisfy GSA’s baseline and Tier 1 High Performance tiling requirements. Green Squared Certified® products that also have an EPD are eligible for use on Tier 2 and Tier 3 federal building projects.

Download PDF

- LEED v4.1

-

LEED v4.1

Under the LEED pilot credit, Certified Multi-Attribute Products and Materials, a point toward LEED certification can be earned by using products from manufacturers who have confirmed multiple environmental attributes through an independent, third-party certification, such as Green Squared®.

In order to achieve this point, at least 25%, by cost, of the total value of permanently installed products in a project must have earned certification under any of the following programs:

- Level® certification for furniture

- NSF 140 certification for carpet

- NSF 332 certification for resilient flooring

- Green Squared certification for tiles and tile installation materials

- UL 100 certification for wall board

- NSC 373 certification for natural stone

- NSF 343 for wallcoverings

- NSF 347 for roofing membranes

Additionally, the product literature must disclose which sections of the relevant multi-attribute sustainability standard were met. An LCA (life-cycle assessment) conforming to ISO 14044 must be available as well, either as a component of or in addition to the product’s multi-attribute certification.

Tiles or installation materials that are Green Squared Certified® and for which an LCA is available (or which meet section 3.8.1 of Green Squared®/ANSI A138.1) can contribute:

Tiles or installation materials that are Green Squared Certified® and for which an LCA is available (or which meet section 3.8.1 of Green Squared®/ANSI A138.1) can contribute:- 50% of the total product cost for baseline certification

- 75% of the total product cost if ANSI 138.1 Level 2 criteria for recycled/reclaimed content and/or Level 2 criteria for indigenous raw materials were met as part of the certification

- 100% of the total product cost if ANSI A138.1 Level 3 criteria for recycled/reclaimed content and/or Level 3 criteria for indigenous raw materials were met as part of the certification

Sample calculation for a project with $1,000,000 in permanently installed products, including $80,000 of Green Squared Certified tile and $20,000 of Green Squared Certified mortar that meets ANSI A138.1 Level 3 criteria for indigenous raw materials:

Tile installation contribution to the 25%, by cost, of the total value of permanently installed products in the project:

(0.5) ($80k tile value) + (1.0) ($20k mortar value) = 6%

$1M (all materials value)

In the example above, the contribution of Green Squared Certified® tiles and installation materials toward the 25% minimum would be 6%.

- ANSI/GBI 01-2021 Green Globes

-

ANSI/GBI 01-2021 Green Globes

Under the provisions of Section 10.2, ANSI/GBI 01-2021 Product Life Cycle, using Green Squared Certified® products can contribute toward the 19 available points for using products with EPDs or that are third-party certified to multi-attribute standards. Points are awarded for using products with:

Points are awarded based on the number of products used, as follows:

Without limit, using Green Squared Certified® tiles or installation materials will contribute to this requirement. Products that also have an LCA or EPD can contribute double.

Without limit, using Green Squared Certified® tiles or installation materials will contribute to this requirement. Products that also have an LCA or EPD can contribute double.Sample calculation for a project with six Green Squared Certified® tiles, six Green Squared Certified® grouts, one Green Squared Certified® mortar, and nine other products certified under their respective industry programs:

13 total tiles / tile installation products + 9 other compliant products

= 22 total products (7 points)Using the above example, tile’s contribution is 13 out of 22 products, or 59%.

Sample calculation for the same project, but with tile that is Green Squared Certified® and has an LCA or EPD:

[(13 Green Squared Certified products with LCA or EPD) x 2]

+

9 other compliant products

= 35 total products (19 points)

Using the above example, although 35 total products are achieved, only 30 are required to obtain the maximum points tier. Toward the threshold, tile’s contribution is 26 out of 30 products, or 87%.

- 2021 IGCC POWERED BY ASHRAE STANDARD 189.1

-

International Green Construction Code (IgCC) Powered by ASHRAE Standard 189.1

About IgCC: An initiative of the International Code Council (ICC), IgCC was developed as model code language for states and municipalities to establish baseline sustainability requirements for new and existing commercial buildings.

About ASHRAE 189.1: An ANSI-accredited standard, ASHRAE 189.1 was written to be incorporated into governing jurisdictions’ codes and ordinances for commercial buildings and enforced by building officials and inspectors.

IgCC and ASHRAE Standard 189.1 are now integrated into a single model code and standard for high-performance buildings.

For compliance with the IgCC, specifically Section 901.4.1.4.3 (ASHRAE 189.1 Section 9.4.1.4.3), Multiple-Attribute Product Declaration or Certification, at least 10 different products installed in the building at the time of occupancy shall have a generic EPD, have a proprietary EPD, conform to a third-party multi-attribute certification, or have a third-party reviewed life cycle assessment (LCA).

Each Green Squared Certified® tile or installation material used on a project counts as two products toward the 10-product threshold, as the Green Squared® standard is one of the multi-attribute certification programs specified by the standard.

Each Green Squared Certified® tile or installation material used on a project counts as two products toward the 10-product threshold, as the Green Squared® standard is one of the multi-attribute certification programs specified by the standard. - NAHB NATIONAL GREEN BUILDING STANDARD

-

NAHB National Green Building Standard

Commonly referred to as ICC 700, NAHB’s National Green Building Standard is an ANSI-accredited specification for residential construction. Green Squared Certified® tiles and installation materials can help achieve points under section 612.2, Sustainable Products.

Three points are awarded if 50% or more, based on square footage, of all tiles installed in a project have been Green Squared Certified. In order for such tiles to qualify, tiles must make up at least 30% of the floor or wall area of the project.

Three points are awarded if 50% or more, based on square footage, of all the tile installed in a project has been Green Squared Certified®. In order for such tiles to qualify, tile in general must make up at least 30% of the floor or wall area of the project.

Three points are awarded if 50% or more, based on square footage, of all the tile installed in a project has been Green Squared Certified®. In order for such tiles to qualify, tile in general must make up at least 30% of the floor or wall area of the project. - GSA P-100 FACILITIES STANDARDS

-

GSA P-100 Facilities Standards

This standard incorporates sustainability criteria into design standards for the construction of government-funded buildings. Section 3.4 (Interior Performance) sets forth several provisions for ceramic tile:

- The “Baseline” and Tier 1 High Performance provisions specify that tiles conform to ANSI A137.1, the ANSI standard for ceramic tile, and be Green Squared Certified®.

- The Tier 2 High Performance and Tier 3 High Performance provisions specify that tiles conform to ANSI A137.1, the ANSI standard for ceramic tile, be Green Squared Certified®, and have a publicly-available EPD.

Green Squared Certified® tiles and installation materials satisfy GSA’s baseline and Tier 1 High Performance tiling requirements. Green Squared Certified® products that also have an EPD are eligible for use on Tier 2 and Tier 3 federal building projects.

Green Squared Certified® tiles and installation materials satisfy GSA’s baseline and Tier 1 High Performance tiling requirements. Green Squared Certified® products that also have an EPD are eligible for use on Tier 2 and Tier 3 federal building projects. - Green Building Credits Summary Chart

-

Download PDF

Six Steps of Certification

The ANSI A138.1 standard and certification of conformance to that standard (Green Squared® certification) were developed specifically to be relevant to products no matter where in the world they are produced. Developed to meet the sustainability needs of the North American marketplace, the Green Squared standard and certification program provide all producers, foreign and domestic, with a clear benchmark for designing sustainable products that can be accepted by North American green building programs.

Here’s what to expect when pursuing Green Squared® certification:

1. Application Process

Manufacturers seeking to have their product(s) certified apply to one of three internationally recognized Green Squared certification agencies:

2. Evaluation

The certification process involves the following in determination of ANSI A138.1

conformance:

-

- General evaluation of the applicant organization

- Product evaluation

- On-site facility evaluation

3. Confidentiality

All proprietary information remains confidential between the certification agency and the manufacturer.

4. Certification

-

- Green Squared Certified® mark awarded by certification agency

- Scope of certified products determined by certification agency

- Certifications valid for a five-year period

- Surveillance audits each year

- Recertification after five years

5. Product Listing

-

- Agency lists all certified products

- Certified products also listed on GreenSquaredCertified.com

- Certified product data syndicated by Ecomedes to Fulcrum, as well as to many public and private A&D purchasing libraries

6. Using the Mark

Once a product is third-party certified as meeting the ANSI A138.1 standard, the certification body awards use of the Green Squared Certified® logo:

-

- Directly on certified products

- Packaging of certified products

- Promotional literature published about certified products

The easily-recognizable Green Squared Certified® mark helps architects, designers, and end users choose products that meet a broad range of sustainability criteria.

The easily-recognizable Green Squared Certified® mark helps architects, designers, and end users choose products that meet a broad range of sustainability criteria.

With so many different brands of green today, Green Squared® certification provides authenticity and conveys that the product certified is the real deal. The Green Squared framework for product evaluation and certification is in accordance with ISO Type 1 environmental labeling and declaration requirements (ISO 14024). In a marketplace

Sustainability Case Studies

The inherent eco-friendliness of tile and tile installation products is amply demonstrated by Green Squared Certified® products.

Besides being robustly sustainable, Green Squared Certified products are also beautiful. The tile and installation products pictured here represent only a handful of the Green Squared Certified products that are currently available. Hundreds of products have been certified, and still more are in the certification process.

Download #OutsideTheBox: Your Tile Buying Guide…and get started now!