Sustainability is a leading priority in today’s building design. Understanding the sustainability features of different building materials helps architects, specifiers, and designers choose the best materials for a project. Recognizing these “green” advantages for flooring requires looking at what a flooring is made of, how it is manufactured, its expected useful life, and how it might be repurposed or disposed of at the end of its service life.

[Related: Ceramic Tile: A Healthy Choice for a Healthy Planet]

What Is Sustainable Flooring?

In general, sustainable flooring has minimal environmental, health, and cost impacts over the life of a building from production to disposal. There are a number of tools and characteristics available that can be used when assessing a flooring material’s sustainability. Many of these work together to determine a material’s overall sustainability footprint:

The definitions and examples we’ve gathered below will help you become familiar with the terms and tools used to describe product characteristics so that you can select the most sustainable choice for your flooring project.

Regional Manufacturing and Naturally-Occuring Raw Materials

Flooring and installation products made with local raw materials greatly reduce the energy consumption and emissions of long-distance shipping. Additionally, the use of raw materials that are in plentiful supply can facilitate a reduced tax on the environment when harvesting.

For example, with ceramic tile manufacturers in many regions of North America, tile and installation products made with local raw materials are widely available. In many cases, the raw materials are mined within 500 miles of both the manufacturing facility and the job site. Plus, the clays and other materials used to make ceramic tile are plentiful.

Life Cycle Cost Analysis (LCCA)

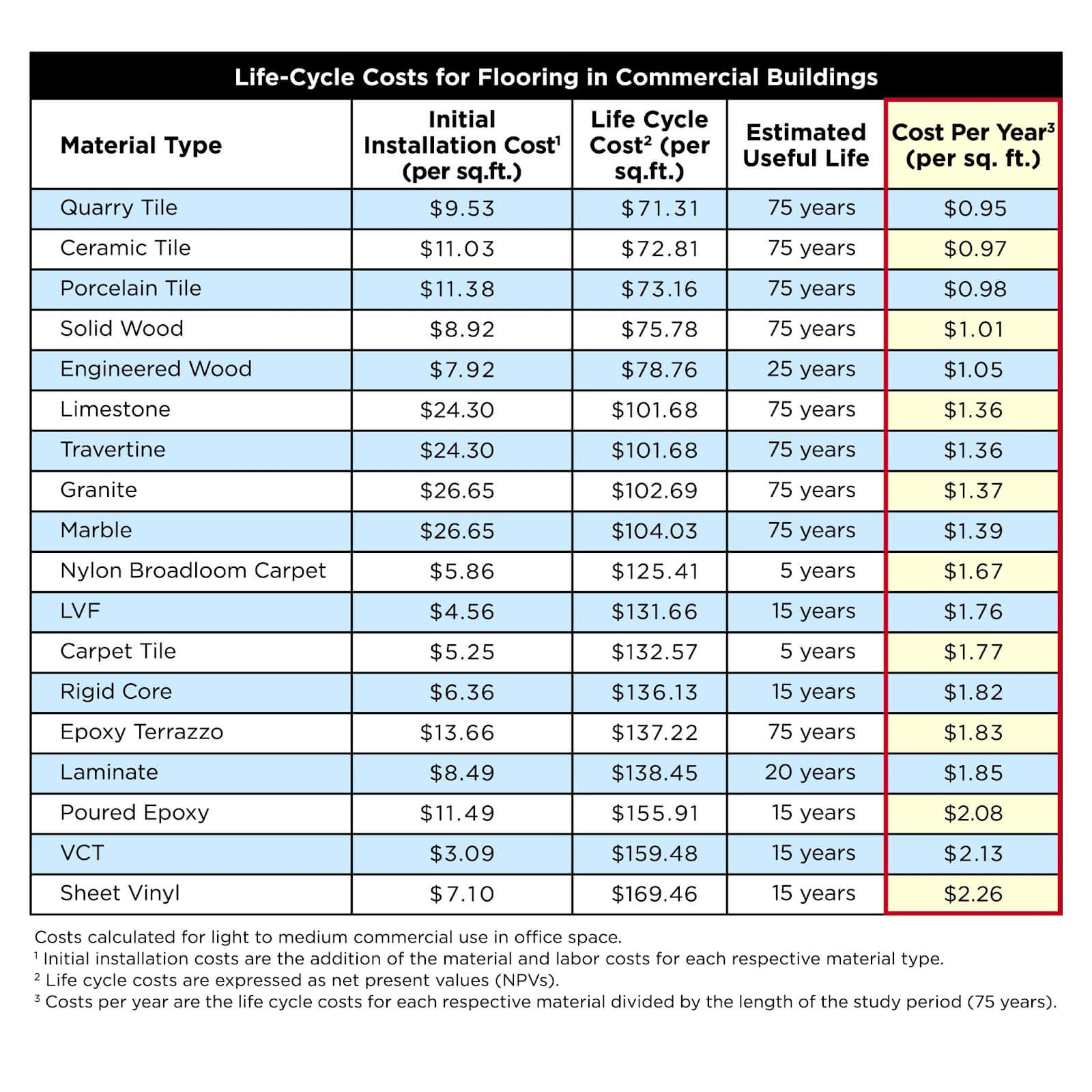

A LCCA is the investment cost of a product or material through its entire life cycle. A LCCA also considers post-production factors such as initial installation costs, replacement costs, and maintenance expenses over the life of a building.

A prime indicator of a low life-cycle cost is that the material has an estimated useful life comparable to the life of the building, which means the flooring won’t need to be replaced. For example, a study by independent cost consultant Emily Lorenz found that when comparing tile, hardwood, laminate, carpet, vinyl, and other popular flooring choices, the ceramic tile family of products (quarry tile, porcelain tile, and ceramic tile) had the lowest costs per year per square foot compared to other flooring types.

Volatile Organic Compounds (VOCs)

Some flooring products can produce Volatile Organic Compounds that can be an issue for people with compromised immune systems, allergies, and other sensitivities. Preferable products should meet the requirements of the state of California’s guidance on VOCs. Ceramic tiles are specifically excluded from testing requirements of VOCs in programs like LEED because they are understood to not contain these chemicals.

Life Cycle Analysis (LCA)

While an LCCA, which we discussed above, considers economic impact, an LCA measures the environmental impact of a building, product, or process from resource collection to end-of-life disposal. For flooring, this analysis includes environmental impacts associated with acquiring a product’s raw materials, manufacturing the product, then delivering, installing, maintaining, and disposing of it, multiplied by the expected number of times the product would need to be replaced (i.e. for a 75-year building, 75 years divided by the product’s service life, in years), as dictated by the North American flooring Product Category Rule (PCR) for Flooring, UL 10010-7. Similarly, the North American Cement-based Grout, Adhesive Mortar, and Self-Leveling Underlayment PCR, UL v1.0 2022, dictates an analysis within the context of a 75-year building.

Environmental Product Declaration (EPD)

An environmental product declaration is a standardized document that reports the results of a material or product’s LCA. EPDs give a wide view of how the particular material or product affects the environment across six major impact categories: global warming potential, eutrophication potential, acidification potential, smog potential, elemental abiotic resource depletion, and fossil abiotic resource depletion.

Following the PCRs discussed above, industry-wide EPDs for North American-made ceramic tile, mortar, and grout report very low 75-year environmental impacts across all six categories, per square meter, due to the inherent durability, long life, and low maintenance of ceramic tile installations.

For example, over 85% of North American ceramic tiles are covered by the industry-wide ceramic tile EPD. The environmental impacts reported by the ceramic tile EPD are significantly lower than those reported by EPDs for flooring composed of plastic-based materials, such as vinyl tile, Rigid Core vinyl (including luxury vinyl tile and planks) and carpet.

EPDs consider these six impact assessment categories from an LCA:

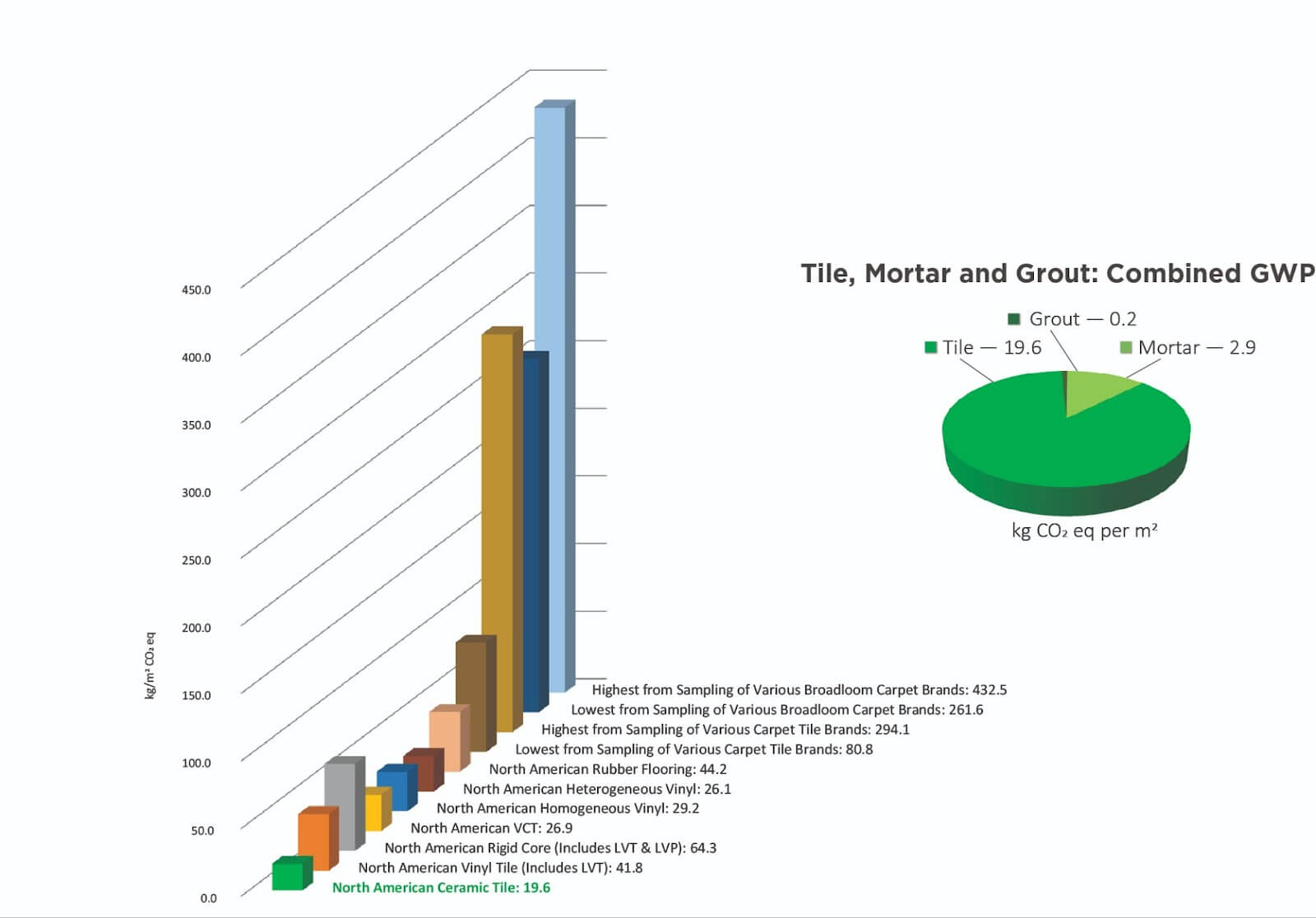

- Global warming potential (GWP)

GWP, commonly referred to as “carbon footprint,” is measured by emissions of carbon-equivalent gases, and relates to climate change. GWP is the key factor used to determine a product’s embodied carbon.

- Ozone depletion potential (ODP)

Ozone depletion occurs when chlorofluorocarbons (CFCs) and hydrofluorocarbons (HCFCs) reach the stratosphere, react with the sun, and break down the ozone layer. Decreased ozone can lead to an increase in the amount of UV-B radiation that reaches Earth’s surface, having harmful effects on human health, animal health, terrestrial and aquatic ecosystems, and biochemical cycles and materials.

- Photochemical Oxidant Creation Potential (PCOP)

PCOP is commonly referred to as smog potential. Smog is harmful to humans and animals, most notably for aggravating bronchial-related diseases. Smog also inhibits plant growth due to increased UV radiation, and can discolor ground-level materials such as building exteriors.

- Acidification potential (AP)

Acidification occurs when soil, groundwater, surface water, and atmospheric moisture pH levels are lowered. This can have a harmful impact on organisms, ecosystems, and man-made materials, including buildings.

- Eutrophication potential (EP)

Eutrophication is the excess enrichment of a body of water (or ecosystem) with nutrients, commonly from fertilizer runoff and sewage. It’s a significant cause of low-oxygen (hypoxic) waters resulting from an increase of plant and algae growth. The National Ocean Service explains that “The excess algae and plant matter eventually decompose, producing large amounts of carbon dioxide that can kill fish and seagrass, and reduce essential fish habitats. The large amounts of carbon dioxide also lowers the pH of seawater slowing the growth of fish and shellfish and can prevent shell formation in bivalve mollusks.”

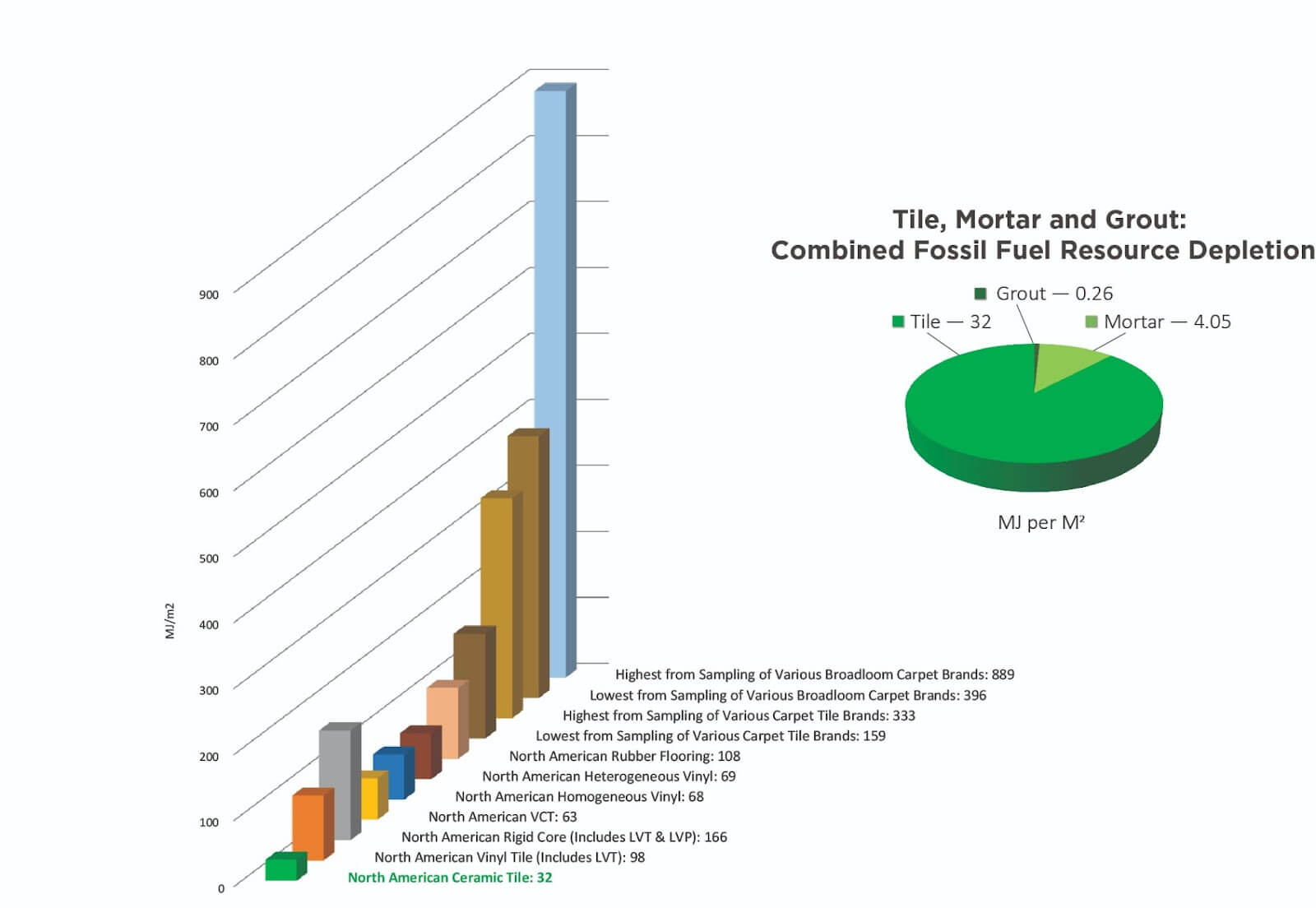

- Fossil fuel resource depletion potential

Fossil fuel resources are primary non-renewable energy resources such as petroleum, coal, and natural gas. The depletion of fossil fuel is considered when used as raw materials, and as fuel in the manufacture, installation, maintenance, and disposal of a product.

Publicly available EPDs for different flooring products help you compare environmental impact assessment categories. For example, when considering GWP, a direct comparison to UL-Certified industry-wide EPDs for ceramic tile, vinyl tile, and rigid core board reveals the following:

- Vinyl tile’s 75-year GWP and fossil fuel resource depletion are two and three times higher, respectively, than ceramic tile’s.

- Rigid core board’s 75-year GWP and fossil fuel resource depletion are three and five times higher, respectively, than ceramic tile’s.

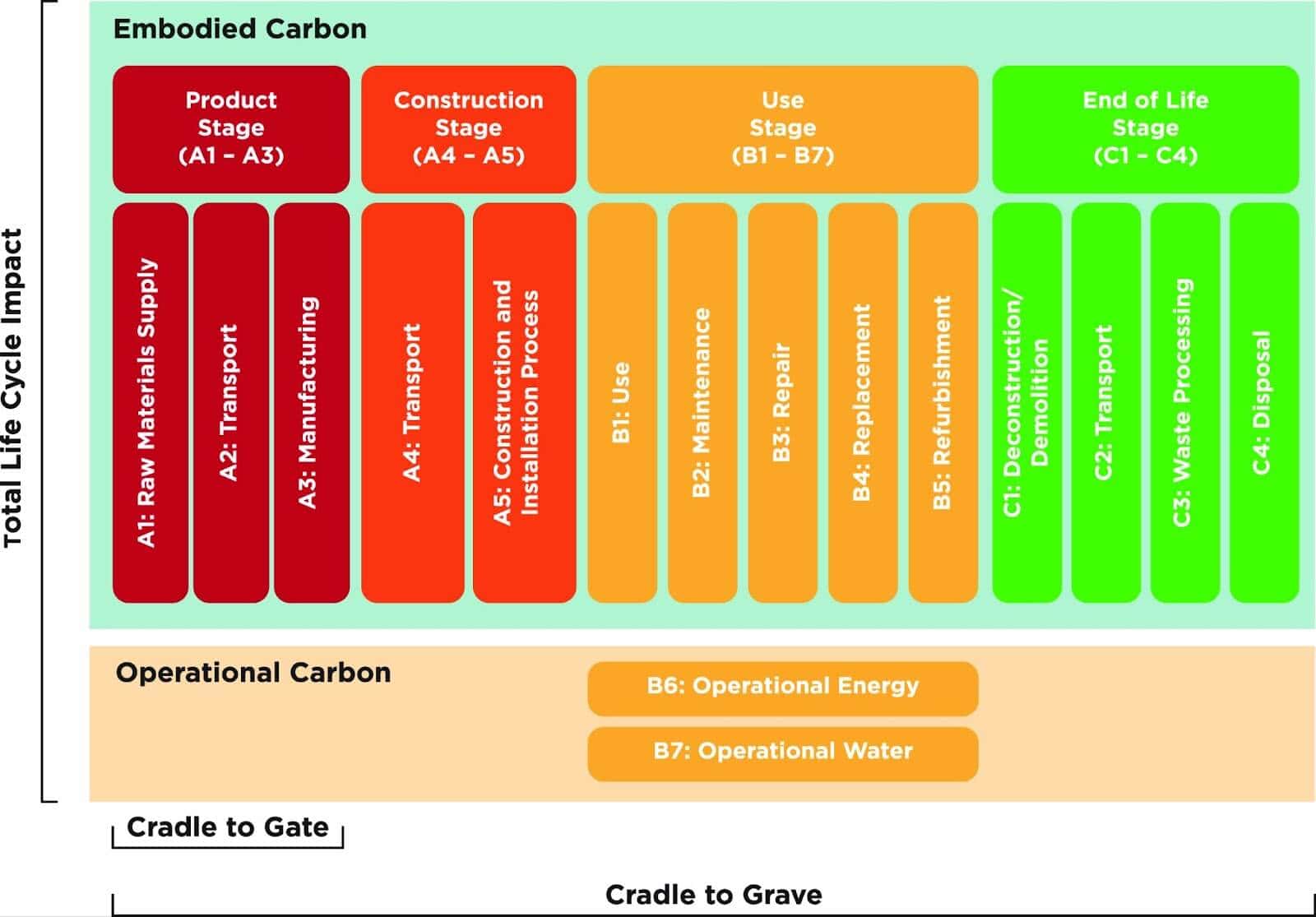

Embodied Carbon

Today, the Global Warming Potential (GWP) impact category is, perhaps, the most sought-after data point reported by EPDs, as it is the basis for determining a product’s embodied carbon. Considering all stages of a product’s life is important when considering a product’s embodied carbon. This means that an EPD with cradle-to-grave LCA data is necessary in order for GWP to be accurately representative of a product’s life cycle — production, construction, use, maintenance, refurbishment and replacement, and end of life.

Given that the North American Flooring PCR, which we discussed above, dictates a 75-year cradle-to-grave EPD, the GWP of products within and across multiple sectors in the flooring category can be compared on a cradle-to-grave basis, assuming each flooring EPD is in conformance with the PCR. Compared to other flooring products that need to be replaced more frequently, ceramic tile performs favorably on a cradle-to-grave GWP basis. Not only does this mean ceramic tile can be a smart choice for reducing embodied carbon in construction, it is both cost-effective and a smart choice for reducing other negative environmental impacts.

Material Ingredient Guide (MIG)

Sustainability programs provide a variety of paths for disclosing the ingredients in the materials being used in a product. In LEED, one option is a material ingredient guide that clearly outlines a product’s material and chemical makeup. MIGs help suppliers and manufacturers quickly and easily provide accurate material content transparency to anyone purchasing their products.

For example, the Material Ingredient Guide created by the Tile Council of North America (TCNA) references in-depth chemical assessments about tile, mortar, and grout ingredients most commonly used by North American manufacturers. It also details health assessments of those materials.

TCNA’s MIG also provides instructions and templates for manufacturers to follow when creating manufacturer inventories (MIs) and health product declarations (HPDs) to assist in obtaining green building optimization credits and comply with green building certification programs.

Green Building Programs

LEED, WELL, and the Living Building Challenge (LBC) are some green building initiatives that rely on assessment tools to define a product’s environmental impact. As reported by the US Green Building Council (USGBC), sustainable construction, such as LEED-certified buildings “is proven to save money, improve efficiency, lower carbon emissions and create healthier places for people. Sustainable construction is critical in addressing the climate crisis, meeting Environmental, Social, and Governance (ESG) goals, enhancing resilience, and supporting more equitable communities.” By using products with a low environmental impact, builders can qualify their projects as sustainably built.

For example, under the LEED pilot credit, Certified Multi-Attribute Products and Materials, a point toward LEED certification can be earned by using products from manufacturers who have confirmed multiple environmental attributes through an independent, third-party certification.

Green Squared Certified® is the world’s only multi-attribute sustainability standard and certification program for ceramic tile and the associated products needed to install tile, which includes ceramic and glass tiles, mortars, grouts, backer-boards, membranes, and other installation materials. Green Squared® is a cradle-to-grave performance standard that eliminates the need to cross-evaluate single-attribute sustainability claims.

For a tile product to be Green Squared Certified® means it meets the American National Standard Specifications for Sustainable Ceramic Tiles, Glass Tiles, and Tile Installation Materials (ANSI A138.1). To be in conformance, products must meet a broad array of rigorous sustainability requirements and electives, as set forth in the standard.

[Related: Guide to Going Green With Ceramic Tile]

What To Look For in Sustainable Flooring

Sustainable flooring materials, such as ceramic tile, share environmentally-friendly characteristics identified through the assessment tools previously discussed. When choosing sustainable flooring, look especially for these characteristics:

- Regional Manufacturing

- Low LCCA

- Low VOC

- Industry-Wide and Product-Specific EPDs

- Material Ingredient Disclosure

- Low Cradle to Grave Embodied Carbon

- Green Squared Certification

Other considerations include:

Exceptional Life-Cycle Cost

As consumers look toward more sustainable and durable flooring products, one needs to consider the impacts and costs over the full life cycle of a building. A low life-cycle cost, such as the family of ceramic tile products, indicates a long useful life and less replacement costs (and less waste into landfills). Consult an LCCA for product comparisons. For specific LCCA flooring product research, consult a laboratory that can perform a custom analysis, such as IPA Laboratories.

Lower Energy Needs

Products with an exceptional life-cycle cost are longer lasting; therefore, less energy is used to source, manufacture, install, maintain, and dispose of, which contributes to less environmental impacts that are often associated with more frequent replacements of other products over the life of a building. Additionally, products such as ceramic tile that are typically sourced and produced without the need of long-distance shipping help reduce energy consumption and emissions. The use of a product that can help reduce future energy consumption is certainly a bonus. Look for products with an exceptional thermal mass, such as ceramic tile. A greater thermal mass helps retain temperature, reducing the load on heating and air conditioning by keeping structures cooler in hot weather and warmer in cold weather.

Recycled Content and Waste Reclamation

Optimum sustainable manufacturing involves factories using “closed-loop” protocols, meaning they have zero waste, high levels of recycling, and efficient resource management. Recyclability or reuse is desirable. Look for transparent information on recycled content understanding that some materials can be difficult or impossible to recycle, such as flooring made with plastics. Products that cannot be recycled or reused may contribute to additional environmental concerns when disposed of at the end of their useful life.

Eco-Friendly Maintenance

Flooring materials that require harsh chemicals for cleaning, or that might require resealing or other routine maintenance, may introduce exposure to toxic substances, and add additional lifetime costs for a flooring product. Look for flooring with simple maintenance such as the easy-cleaning routine for ceramic tile. Clean water is often all that is necessary for cleaning ceramic tile products.

[Related: Sustainable Case Studies]

Ceramic Tile is a Top Choice for Sustainable Flooring

Taking steps toward a greener future by making smart, sustainable choices is crucial to our planet’s well-being.

Learn more about the sustainability advantages of ceramic tile:

- Explore tile’s eco-friendly benefits.

- Download the EPD and EPD transparency summary for ceramic tile.

- Review the green building credits and requirements that are possible with tile.

Find design inspiration with our searchable design gallery, knowing that the choice of ceramic tile is a healthy choice for the planet!